OQC

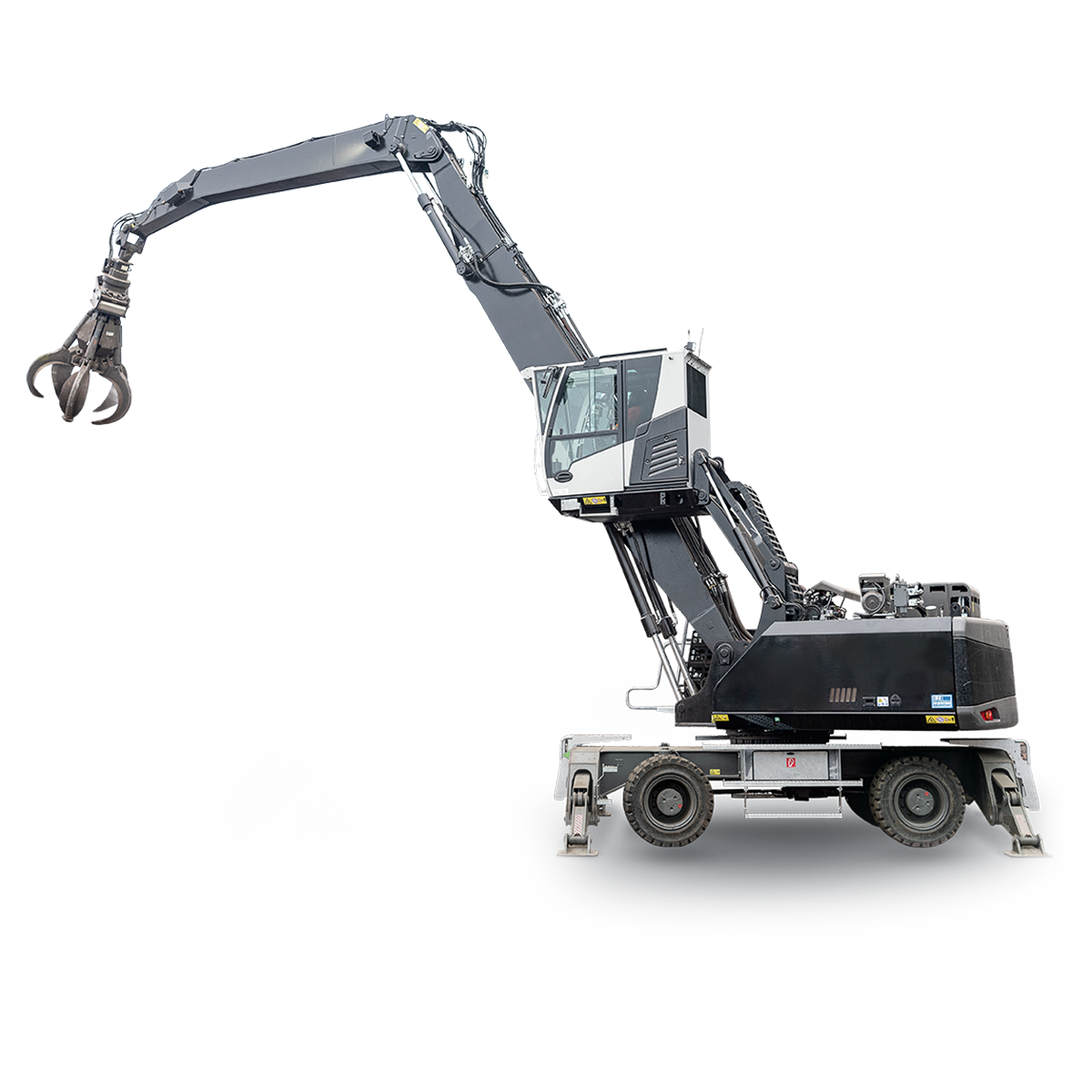

Automatic quick coupler system for material handlers/cranes

Change hydraulic attachments in 15 seconds

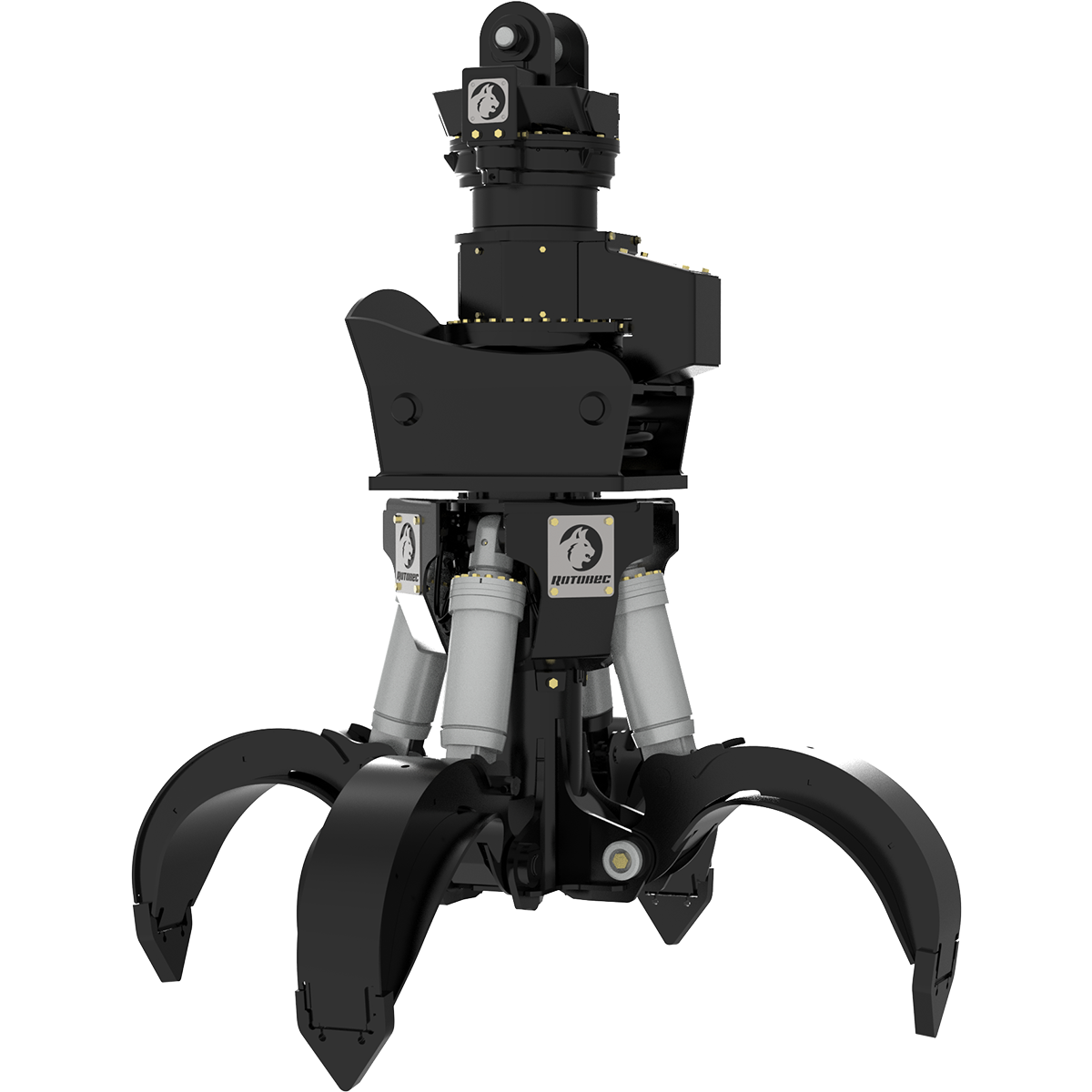

The OQC is an OilQuick suspended quick coupler, which is primarily designed for use on material handlers/cranes. The system consists of an extremely rugged 360° rotator mounted on our fully hydraulic, tried-and-tested quick coupler. The OQC unit is suspended from the handling equipment’s stick.

- Over 20 years’ experience with fully automatic quick coupler systems.

- Maximum cost effectiveness and flexibility - being able to use the right attachment makes the machine a versatile tool carrier. This enables capacity utilization to be maximized and process flows optimized.

- Tailored applications - wide range of work tools available, with the option of using special/custom attachments.

- Secure connection within seconds - simple and safe changing of hydraulic, mechanical and electrical work tools from the operator’s cab.

- Quick couplers from OilQuick - have proved their worth on job sites thousands of times.

- Integrated electric swivel - lifting magnets can be used without additional cables having to be laid manually from the machine to the plate.

- Maximum flexibility - 360° continuous rotation for all work tools with heavy-duty motor.

OQ Safety System (OQSS)

OilQuick Safety System (OQSS) is a new system for controlling your OilQuick coupler. OQSS gives operators more control and better feedback on the status of the coupler and tool, in addition to tougher hardware that will last longer.

- Newly designed in-cab controller interface with integrated troubleshooting capabilities

- Addition of lock pressure monitoring that provides redundant monitoring of proper coupler engagement

- Better Hardware: heavy duty wiring harnesses for improved durability and ease of installation

- Simplified setup procedure

- Adheres to ISO standards for quick coupler safety